Understanding Vehicle Air Con Compressor Failures: Common Causes and Solutions

Understanding Compressor Failures: Common Causes and Solutions

When it comes to automotive air conditioning systems, the compressor is a crucial component. At Auto Air Gloucester Ltd, we ensure that every compressor is rigorously tested before shipping to guarantee its functionality. However, it’s important to understand that compressors can fail shortly after installation for various reasons. This doesn’t always indicate a faulty unit. Here are some common causes of compressor failure:

- No Oil Added: A lack of oil can lead to immediate compressor failure.

- Too Much Oil Added: Overfilling with oil can cause liquid lock, leading to clutch and pulley failure.

- Too Little Oil Added: Insufficient oil can burn out the compressor and clutch, causing pulley failure.

- Incompatible Oil Added: Using the wrong type of oil can damage the compressor.

- Unrectified Initial Compressor Failure: If the initial fault isn’t corrected, the problem may recur, possibly manifesting elsewhere in the system.

- Blocked Expansion Valve: A blocked valve that isn’t changed or cleaned can impede system functionality.

- Unchanged Drier: Not replacing the drier, as required by warranty conditions, can cause issues.

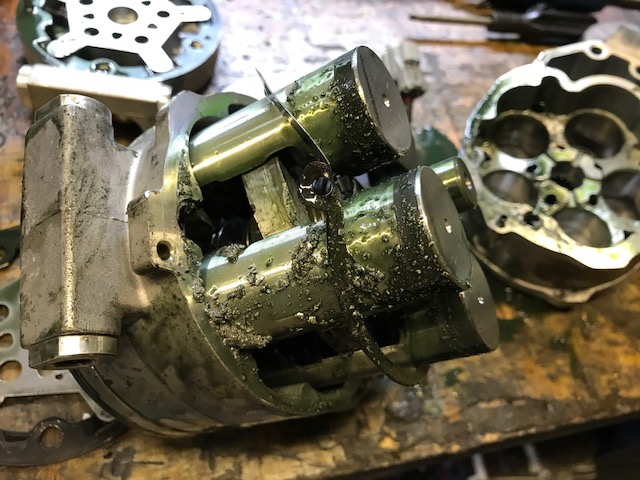

- System Debris: Debris from an improperly flushed system can cause noise, seizure, and pulley failure.

- Pressure Sensor Failure: A malfunctioning pressure sensor can lead to compressor problems.

- Incorrect Refrigerant Levels: Using too much or too little refrigerant can cause system issues.

- Improper Installation: Not following installation and warranty instructions correctly can lead to failures. Detailed instructions can be found here.

- Faulty Compressor: Though rare, a compressor may indeed be faulty.

A compressor does not fail without reason. Identifying and rectifying the root cause of the initial failure is crucial to prevent a recurrence. If your compressor fails, it’s essential to determine whether the issue is due to a faulty unit or another factor.

What to Do If Your Compressor Fails

To accurately diagnose and address the issue, we need to inspect the unit. We cannot issue a replacement without verifying the warranty to avoid repeated failures. For detailed warranty information, please refer to our warranty and returns page.

Ensuring Proper Installation and Maintenance

Proper installation and maintenance of your compressor are essential to its longevity and efficient operation. Always follow the manufacturer’s guidelines and ensure all components of the system are compatible and in good condition. This includes regular checks and replacements of the drier, ensuring the expansion valve is clean and unblocked, and maintaining the correct refrigerant levels.

If you have any questions or need further assistance, feel free to contact us. We are here to help ensure your air conditioning system runs smoothly and efficiently.